Forklift Training & Certification

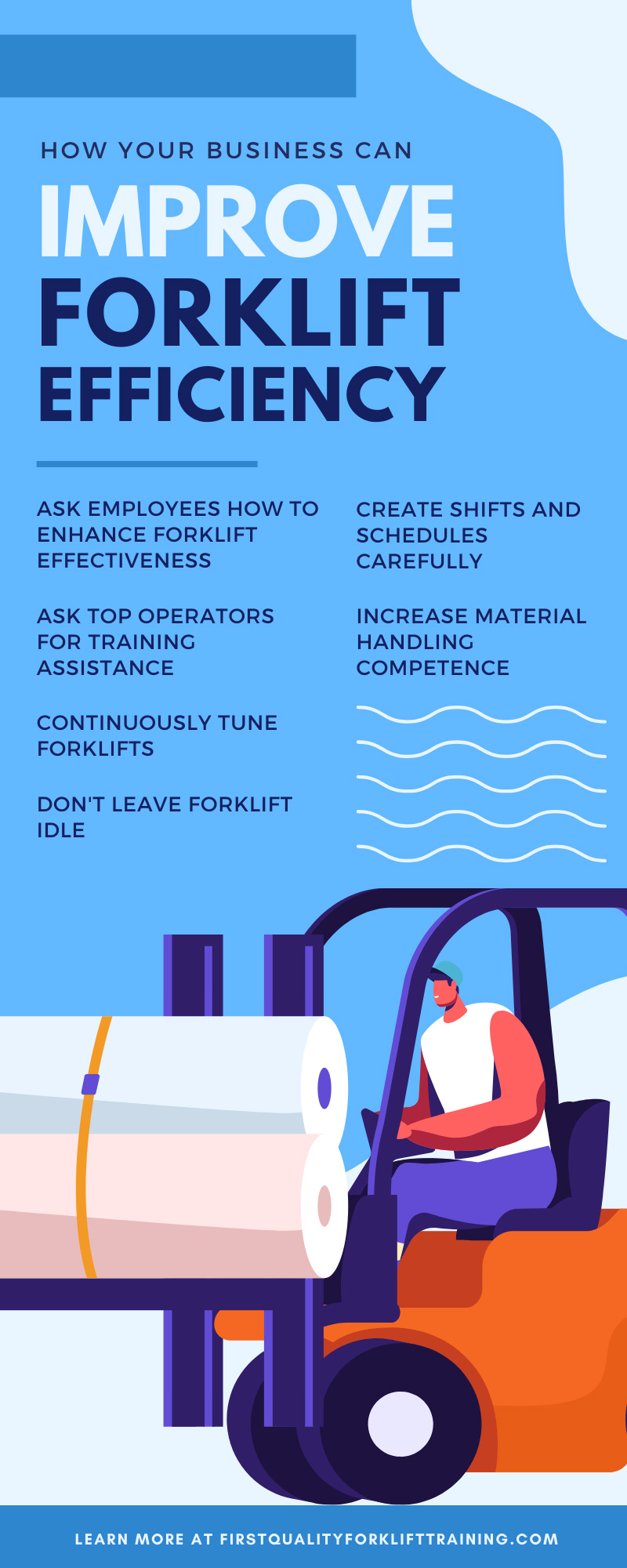

How Your Business Can Improve Forklift Efficiency

Learning how to operate a forklift is one of many things several businesses note as a better way to increase productivity and enhance the work experience. Let’s dive in and explore how your business can improve forklift efficiency.

Ways To Increase Forklift Efficacy

As we learn how to accommodate our businesses for forklifts, we need to know how to increase forklift proficiency while on the job and when training new forklift operators. One can optimize efficacy through telematics.

Telematics is a cellular networks system with installed devices in forklifts for data transmitting to a hosted server through your provider.

Before using telematics, determine the use of each forklift. For instance, certain data needs tracking. The following is what to look over:

- Forklift placement

- Idle forklifts

- Daily maintenance checks

- How employees treat the equipment

After studying the data through your telematics system, your business can analyze the data for fleets.

The recorded figures examined contain information that expands the proficiency of your forklift.

Ask Employees How To Enhance Forklift Effectiveness

As you learn how your business can improve forklift efficiency, reach out to the operators for suggestions.

Right before you ask, here are two ways to help increase the ability of forklift operations.

Ask Them To Describe a Task

Your workers are a vital part of the business, so suggestions should come from your group of workers. For example, ask one of your employees to describe a task they perform and write out every step involved in the job.

After writing it out, ask the workers what changes they’d make and how they would make the task better.

Observe Your Top Operators

Your top workers are the ones that know the simplest tricks to operating and helping better the proficiency of forklifts.

As you watch your top operators, persuade them to pass on their knowledge to other workers to help them better their skills.

Ask Top Operators for Training Assistance

Many supervisors need prime examples of what to do on the job while also being safe and ensuring forklifts are in operable condition.

While in training sessions, have your top talent assist you in demonstrating actions that are appropriate while on the forklift and how to do maintenance checks before operating.

Keep Communication Flowing With Operators

It doesn’t matter who ranks as the top forklift operator; all workers need to know changes to processes and other work functions.

As you undergo new procedures, schedule a meeting to explain all the changes. Ensure your workers understand why you make specific changes and know how to add them to their current process.

Improve Fuel for Forklift Efficacy

An additional part of improving the effectiveness of forklifts is to improve fuel utilization. So, right before you maintain your fuel, here are some tips to follow.

Continuously Tune Forklifts

While fine-tuning forklift competence for your business, you also need to care for your fuel usage. Without fuel or daily maintenance checks, you wouldn’t have a way to operate your business effectively.

So, while performing an evaluation, continue looking over the engine and fix any problems as soon as you spot them.

By being proactive in fixing and tuning your machine, you not only save on fuel costs, but CO emissions also decrease.

Doing tests often for carbon monoxide can help determine when your forklifts need tuning. After examining and fixing the issue, your forklift’s fuel proficiency adjusts; hence, the chance of CO emissions lowers.

Don’t Leave Forklift Idle

As mentioned above, when looking at data from your telematics system, check when forklifts are left idle.

When forklifts are left unused and turned on, they transmit considerable amounts of CO, which is harmful.

Therefore, when you’re not using the forklift, it’s better to leave it off to prevent CO from transferring into the air.

Be Consistent With Speed

Working with a forklift isn’t a race. It’s more dangerous to drive in a manner that exceeds the operator’s ability to bring the forklift safely to a stop.

When you move excessively fast, you run the risk of wasting fuel. So, to save on energy and not drain the batteries, drive it at the appropriate speed.

While you’re in team meetings, remind your operators to avoid pushing the limit on the gas pedal. That way, they can avoid injury and time on refueling the engine.

Additionally, they avoid injuring themselves and others, causing tire wear, and cutting down on refueling the engine.

Check on Your Tires

Another area to focus on is your tires. When improving the effectiveness of forklifts in your business, inspecting the tires can save money on fuel and prevent any additional damage to your tires.

Driving becomes complicated when the wheels are damaged, forcing the engine to work harder and waste more fuel.

Continuing daily maintenance, which includes checking the engine and wheels, helps lower the chances of using too much gas. Performing daily maintenance checks increases the productivity of your forklifts, saving you money.

Increase Material Handling Competence

As you prepare your productivity plan, the next area to focus on is proper material handling through shipping and receiving in and around the loading dock. Follow these tips to help organize shipping and receiving.

Create Shifts and Schedules Carefully

When improving the effectiveness of a business model, we need to look at areas that need the most organization, such as shipping and receiving.

When dealing with either, it can lead to problems, like miscounting goods, damaging items, and sometimes injury if we’re not careful.

So, to help figure out the best-case scenario when loading and unloading, consider optimizing the material handling portion.

When scheduling truck arrivals and departures, you want to plan, if possible, separate times to give you and your workers enough time to process all loads in a timely manner efficiently.

Moving time frames around can help limit the number of dock doors used, saving money on utilities.

Your Order Packing Progression

Before making changes and enforcing them, consider how every order is packaged and placed in the warehouse.

Check for Sufficient Space

When operators work around packages, they don’t want to go through a maze or squeeze through piles of shipments. Instead, create a layout that’s easy to follow and that workers can move in and out of easily.

Better Work Speed

If you’ve noticed that there’s not enough time in the day to finish packing, there might be a lack of urgency.

Some employees simply don’t know how long you expect certain tasks take to complete.

Many people find themselves more productive when large tasks are broken down into smaller milestones because they feel satisfied when completing each goal. The main objective is to ensure workflow is even and they complete tasks on time.

So, gather your team and discuss what areas need changing, such as moving employees to different places to complete a job on time.

As your business progresses, refining employees’ forklift operating skills must continue. Moving forward, purchase a forklift training kit through First Quality Forklift Training to develop competency.

First Quality Forklift Training provides training kits for forklift operators. Our programs push businesses ‘ progression towards becoming more efficient with forklifts. Continue browsing our training kits to enhance and increase your employees’ skillsets and knowledge.