Forklift Training

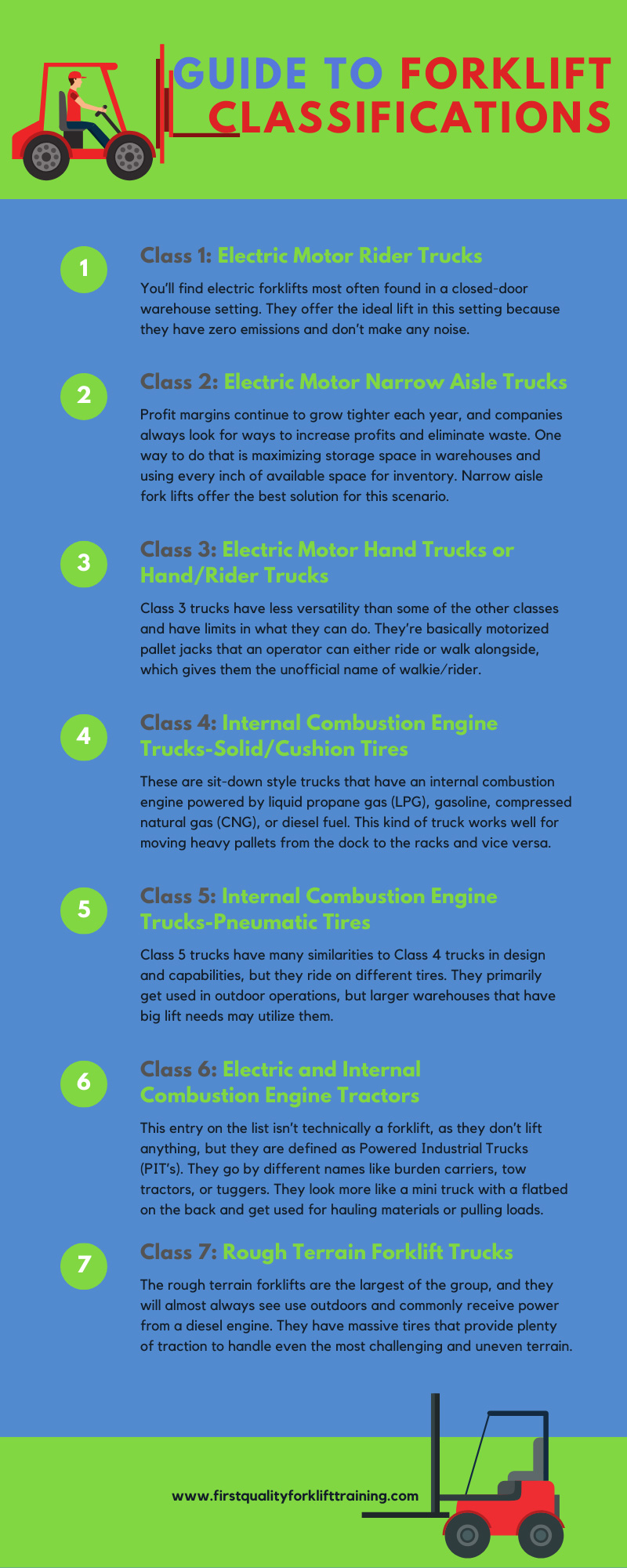

Guide to Forklift Classifications

Since their invention in the early twentieth century, forklifts became a ubiquitous part of the warehousing and logistics industry. The work they can do, the loads they can lift, and the speed at which they can do it makes them invaluable. Efficiency and speed in the warehouse setting have a huge importance as the speed of commerce continues to increase. Forklifts essentially make it possible to keep up with the new demands. Finding and buying the right forklift for the operation is important. With so many kinds of powered industrial trucks available, however, knowing what you need can feel confusing. Forklifts come in seven different classes to help managers and administrators find the right one for their needs.

We offer a guide to forklift classifications, what they mean, and their features to help you find the right truck for your business.

Class 1: Electric Motor Rider Trucks

You’ll find electric forklifts most often found in a closed-door warehouse setting. They offer the ideal lift in this setting because they have zero emissions and don’t make any noise. Electric models glide safely around the warehouse, creating much less noise than other models. These features make them ideal for proximity work, like loading and unloading tractor trailers, and for warehouses that store food.

Class 2: Electric Motor Narrow Aisle Trucks

Profit margins continue to grow tighter each year, and companies always look for ways to increase profits and eliminate waste. One way to do that is maximizing storage space in warehouses and using every inch of available space for inventory. Companies build racks higher, squeeze them in tighter, fill every cubic inch of space possible, and make the layout conducive for work flow. Narrow aisle forklifts offer the best solution for this scenario. They’re generally compact, and operator stand-up style trucks work perfect for this kind of set up. The pinching of the racks makes a narrow aisle truck a necessity because of their ability to reach high and pick pallets in tight spaces that a normal sit-down truck can’t access.

Class 3: Electric Motor Hand Trucks or Hand/Rider Trucks

Class 3 trucks have less versatility than some of the other classes and have limits in what they can do. They’re basically motorized pallet jacks that an operator can either ride or walk alongside, which gives them the unofficial name of walkie/rider. The operator hand controls the truck with a steering tiller and the controls mounted on top. Variations in the design of class III electric motor hand trucks or hand/rider trucks allow them to carry one or two pallets, and they provide the ideal way to load and unload trailers. In a pick pack operation, the walkie/rider is good for riding from location to location and pulling orders. Most trucks in this class only lift the pallet a few inches off the ground, but there are a few that can lift a pallet high enough for an upper rack location six feet off the ground.

Class 4: Internal Combustion Engine Trucks-Solid/Cushion Tires

These are sit-down style trucks that have an internal combustion engine powered by liquid propane gas (LPG), gasoline, compressed natural gas (CNG), or diesel fuel. This kind of truck works well for moving heavy pallets from the dock to the racks and vice versa. Though indoor operations commonly utilize electric trucks, gas powered trucks are used indoors when the warehouse has limited space for battery charging stations or limited time to recharge. You can refuel an internal combustion truck much faster than a battery can recharge. Cushion tired trucks tend to ride lower than pneumatic tired ones, making the well suited for low clearance situations and tight spaces.

Class 5: Internal Combustion Engine Trucks-Pneumatic Tires

Class 5 trucks have many similarities to Class 4 trucks in design and capabilities, but they ride on different tires. They primarily get used in outdoor operations, but larger warehouses that have big lift needs may utilize them. Instead of the solid tires that the Class 4 indoor trucks use, pneumatic tires are filled with air, foam, or a combination air/foam, which makes them ideal for rough outdoor surfaces. A massive load capacity makes this type of truck ideal for outdoor spaces like lumber yards, scrap yards, and docks to lift huge shipping containers. They come in single- or double-wheel configurations, and receive power from by LPG, diesel, compressed natural gas (CNG), or gasoline.

Class 6: Electric and Internal Combustion Engine Tractors

This entry on the list isn’t technically a forklift, as they don’t lift anything, but they are defined as Powered Industrial Trucks (PIT’s). They go by different names like burden carriers, tow tractors, or tuggers. They look more like a mini truck with a flatbed on the back and get used for hauling materials or pulling loads. The most recognizable example of this truck is at the airport. They pull a train of luggage cars back and forth from the plane to the terminal. Exposition spaces that host trade shows and theaters also use these trucks to transport sets and displays around the massive spaces. Some versions resemble golf carts with a steering handle and space for two passengers with a limited load capacity on the back.

Class 7: Rough Terrain Forklift Trucks

The rough terrain forklifts are the largest of the group, and they will almost always see use outdoors and commonly receive power from a diesel engine. They have massive tires that provide plenty of traction to handle even the most challenging and uneven terrain. You will typically find them on construction sites, lumber yards, and shipping docks. Available in two- or four-wheel drive, they can come equipped with telescoping masts to increase their reach. A high load capacity and durability make them a popular choice for material handling on a large scale. Due to their size, they need a lot of room to turn and maneuver, making them a poor choice for cramped indoor use. They include vertical mast (similar to Class V forklift but 4-wheel drive), variable reach e.g. telehandler, and truck/trailer mounted e.g. Sellick.

No matter what kind of truck the business needs, ensuring your operators fulfill OSHA forklift training requirements is the law.