Forklift Training & Certification

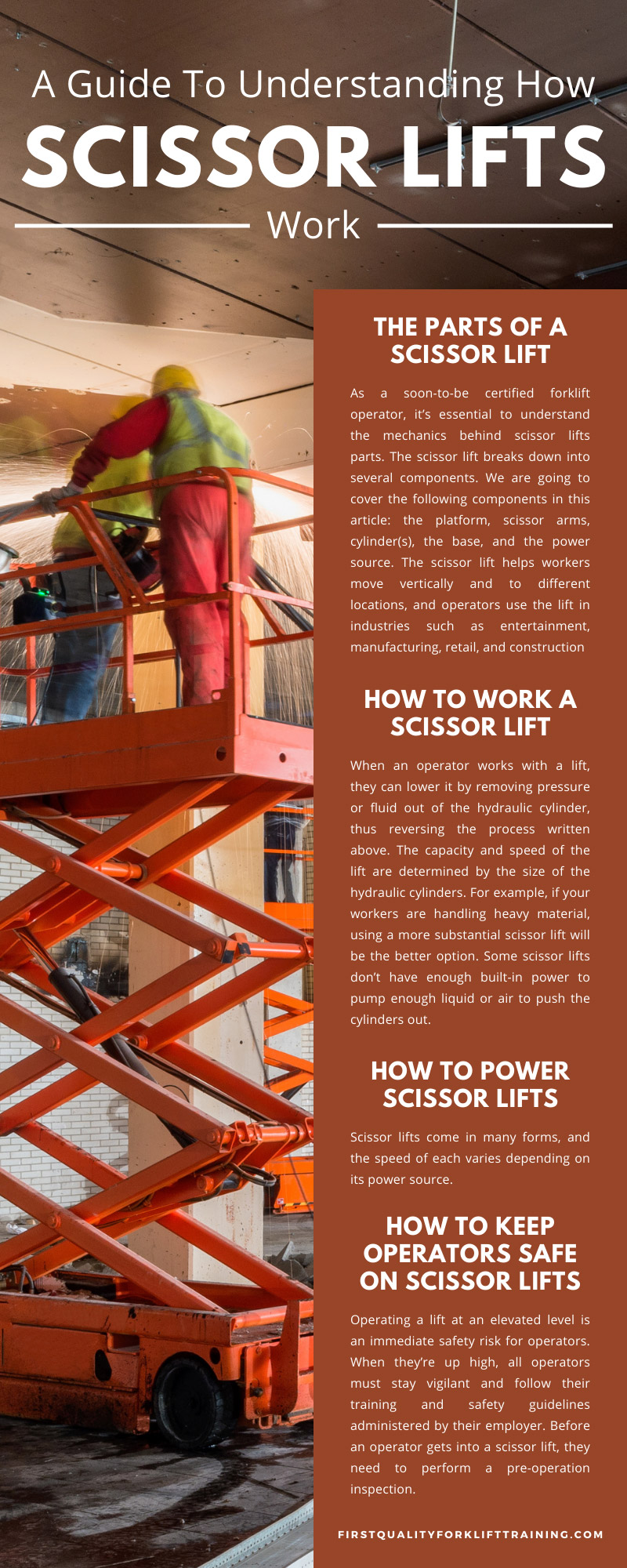

A Guide To Understanding How Scissor Lifts Work

Our guide will help you and your employees understand the mechanics behind a scissor lift and the different types. The guide to understanding how scissor lifts work explores how each part functions and concludes with how your workers can learn how to operate one safely.

The Parts of a Scissor Lift

As a soon-to-be certified forklift operator, it’s essential to understand the mechanics behind scissor lifts parts. The scissor lift breaks down into several components. We are going to cover the following components in this article: the platform, scissor arms, cylinder(s), the base, and the power source. The scissor lift helps workers move vertically and to different locations, and operators use the lift in industries such as entertainment, manufacturing, retail, and construction.

The Platform

The platform, also called a lift table, is where workers transport themselves through each level of their work. The platform can come in many sizes.

The Base

Similar to the platform, the base can vary in size. It’s made of rigid metal and is the foundation of the scissor lift. The bottom houses many of the mechanics that move the lift up and down. It also contains the drivetrain that moves workers and supplies to the location where professionals are going to perform the work.

The Scissor Arms

The scissor arms extend from the base to the platform, and as they rise, the arms constrict. When the legs lower themselves, they expand. There are two scissor arm design types: pantograph and crisscross pattern.

The Cylinder(s)

The cylinders of a scissor lift are its most important tool. They house the fluid which is necessary for the lift to move up and down to transport employees and supplies to multiple floor levels. If a scissor lift doesn’t have hydraulic fluid, it won’t function.

The Power Source

The scissor lift has a wide range of power sources. Some models need a self-contained battery-operated motor, while others might operate via an internal combustion engine. A scissor lift can be powered in many different ways, which we’ll review later.

The Down Valve

The down valve helps control the amount of fluid going into a scissor lift. It also gives a user the ability to control how much fluid they use. The down valve is an excellent part of the overall functioning of the lift; when used, it won’t descend as fast. It should be noted that lowering a scissor lift is much faster than raising a scissor lift. However, nervous workers won’t need to worry about scissor lifts automatically lowering too quickly.

The Flow Control Valve

The flow control valve manages how much hydraulic fluid gets used. In this way, it’s similar to the down valve. Therefore, it controls the upward movement speed of a scissor lift as it travels.

How To Work a Scissor Lift

The power source used when operating a scissor lift determines how it works. However, all scissor lifts move the same way. They seem simple at first glance, but it takes time and patience to learn how to operate one. When you’re in scissor lift training, you’ll learn about the factors below.

- When the lifting of the platform is desired, the cylinders fill with hydraulic fluid

- When filled, the piston is pushed through the hydraulic cylinder from one end to the other end.

- Once the cylinder pushes out, the scissor arms start to separate, and then the platform is raised.

When an operator works with a lift, they can lower it by removing pressure or fluid out of the hydraulic cylinder, thus reversing the process written above. The capacity and speed of the lift are determined by the size of the hydraulic cylinders. For example, if your workers are handling heavy material, using a more substantial scissor lift will be the better option. Some scissor lifts don’t have enough built-in power to pump enough liquid to push the cylinders out.

How To Power Scissor Lifts

Scissor lifts come in many forms, and the speed of each varies depending on its power source. Below is a summary of extremely common scissor lifts and how they operate on different power types.

Diesel Lifts

Diesel lifts are powered by a diesel engine. This type of lift has better weight management and comes with a vast platform. However, it’s best to use diesel lifts outdoors since the ventilation is better than indoors, and noise pollution is condensed.

Electric Lifts

The electric lift powered by batteries is quiet and powerful. Workers can keep the lift in small areas without disrupting activities around them. Since electric batteries don’t emit toxic fumes, they’re also an excellent option for sustainability and perfect for tight spaces in a warehouse.

How To Keep Operators Safe on Scissor Lifts

Operating a lift at an elevated level is an immediate safety risk for operators. When they’re up high, all operators must stay vigilant and follow their training and safety guidelines administered by their employer.

Before an operator gets into a scissor lift, they need to perform a pre-operation inspection. This visual inspection needs to be performed by the operator prior to each work shift. The pre-op inspection includes ensuring items are in working order. Some items to look at include the overall condition of the scissor lift and the emergency stop button functions. Also, workers need to practice safety, such as making sure there are no hazards around.

If you’re looking to help your workers gain a better understanding of scissor lifts, look no further than First Quality Forklift Training. We have the essentials needed for MEWP operator training for you and your workers. Start learning about scissor lifts and other equipment by looking at the vast array of training kits made to help improve the skillsets of your forklift operators