Forklift Training & Certification

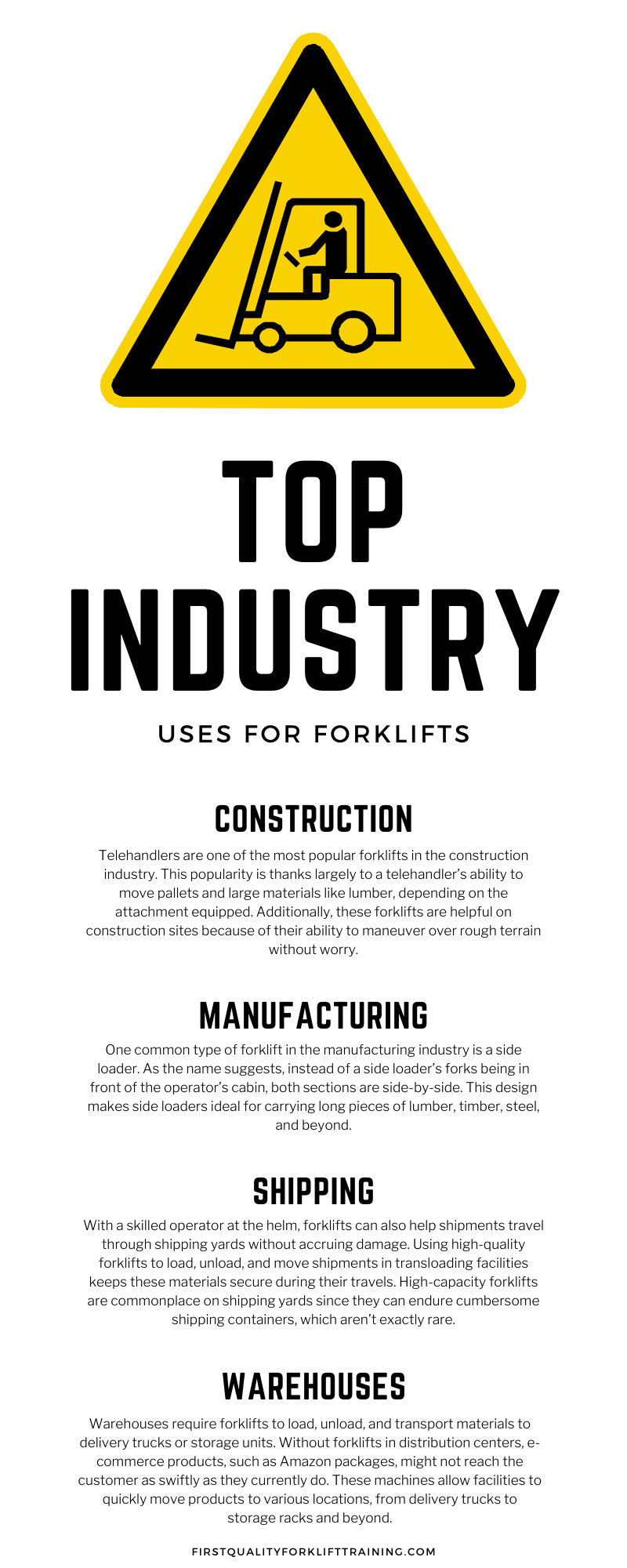

Top Industry Uses for Forklifts

Forklifts are commonplace in a diverse group of industries. This breakdown of the top industry uses for forklifts will detail how major businesses rely on certain lift trucks to thrive, from telehandlers to side loaders.

Construction

Construction sites need a suitable means of transporting pallets of steel, bricks, wood, and other building materials. A bevy of specialized forklifts are on the market, some of which are particularly useful for loading and unloading pallets from delivery trucks.

When delivery trucks with heavy cargo such as work equipment and building materials arrive at a construction site, forklifts can make the process of getting the supplies where they need to go more efficient and stress-free. Obviously, transporting pallets brick by brick isn’t exactly efficient. Thanks to forklifts, employees can swiftly transport the whole pallet in one go.

Telehandlers are one of the most popular forklifts in the construction industry. This popularity is thanks largely to a telehandler’s ability to move pallets and large materials like lumber, depending on the attachment equipped. Additionally, these forklifts are helpful on construction sites because of their ability to maneuver over rough terrain without worry. Not all forklifts can handle heavy terrain, but telehandlers can.

Not only do forklifts improve efficiency on construction sites, but they also help create a more ergonomic work environment. If employees are consistently asked to carry cumbersome loads, it can potentially cause injuries in the back, neck, and wrists. By providing employees with the right equipment to safely move heavy materials, businesses can prevent staff from enduring such injuries. Since there are so many different types of forklifts that operate in vastly different ways, operators should receive specialized training on each.

Luckily, finding suitable RT forklift training programs and other courses for specific forklift types is far from difficult. With the proper training in whichever forklift type your facility utilizes, operators can transport loads safely and securely.

Manufacturing

Manufacturing facilities are widespread, excelling in the production of various goods. To transport these goods with both employee health and workplace productivity in mind, manufacturing facilities use forklifts. Materials such as automobile, boat, or aircraft parts, lumber, custom fabricated metal, and electronic devices are only a handful of the materials commonly transported through specialized manufacturing facilities.

For instance, employees in car manufacturing facilities aren’t exactly carrying heavy car parts over their shoulders. Likewise, while one laptop is light enough to carry by hand, a whole shipment of them can be quite heavy. These materials require immense care and strength to transport around the workplace, which is why forklifts are so invaluable to manufacturers. As they do on construction sites, forklifts make material transportation in manufacturing facilities both efficient and safe.

One common type of forklift in the manufacturing industry is a side loader. As the name suggests, instead of a side loader’s forks being in front of the operator’s cabin, both sections are side-by-side. That might not sound special at first, but these lifting tools are specially built to carry wide, heavy loads. This design makes side loaders ideal for carrying long pieces of lumber, timber, steel, and beyond. Additionally, side loaders are slimmer than your traditional lift truck, making them more suitable for traveling down narrow aisles.

In applicable work environments, optimizing aisle size to accommodate side loaders can help manufacturers better use the facility’s floor space. In other words, aisles and storage racks can cover less ground because they don’t have to accommodate larger forklift models.

Shipping

Shipping yards are home to massive, heavy metal containers that transport a wide array of materials. To move these containers around shipping yards in a productive manner, heavy-duty machines like forklifts are necessary. In fact, forklifts have been a crucial part of handling dockyard shipments since World War II. The reason these heavy-duty trucks remain so vital to the industry today is that forklifts still offer the power and productivity necessary to move large shipping containers.

With a skilled operator at the helm, forklifts can also help shipments travel through shipping yards without accruing damage. For example, there’s a process within the shipping industry called “transloading.” This term refers to transferring a shipment of goods from one mode of transportation (truck, train, barge) to another. Transloading facilities offer goods manufacturers a way to transport products to clients promptly.

The transferring of these products between multiple vehicles increases the likelihood of products sustaining damage before reaching their destination. Obviously, this is something manufacturers would like to avoid. Using high-quality forklifts to load, unload, and move shipments in transloading facilities keeps these materials secure during their travels. High-capacity forklifts are commonplace on shipping yards since they can endure cumbersome shipping containers, which aren’t exactly rare.

Warehouses

By far, one of the top industry uses for forklifts is shipment handling in warehouses and distribution centers. Similar to shipping yards, warehouses build a strong reputation due to how efficiently and reliably they handle products. Warehouses and distribution centers are responsible for ensuring a manufacturer’s goods remain out of harm’s way as they move through the facility.

Warehouses require forklifts to load, unload, and transport materials to delivery trucks or storage units. Without forklifts in distribution centers, e-commerce products, such as Amazon packages, might not reach the customer as swiftly as they currently do. These machines allow facilities to quickly move products to various locations, from delivery trucks to storage racks and beyond.

When it comes to finding the right forklift for warehouses, managers have to consider the type of forklift they’re buying. More specifically, warehouse managers have to know whether a forklift is better for indoor or outdoor use.

Understanding the difference between indoor and outdoor optimized forklifts is crucial. Not all forklifts can handle the same terrain. Plus, some forklifts aren’t safe to use indoors. For example, diesel-powered forklifts are exceptional when it comes to transporting heavy loads over rough terrain.

Unfortunately, using them in most indoor environments can cause dangerous fumes to accumulate. On the other hand, battery-powered forklifts don’t give off the same emissions diesel-powered types do, making the former optimal for indoor material handling tasks. Forklifts aren’t something you should buy blindly—thorough research is always important. Employees can accomplish many tasks with forklifts, but you have to find the right one for your needs. Finding the perfect forklift might take some time, but it’s well worth the effort if you’re a part of any of the above industries.