Forklift Safety, Forklift Training & Certification

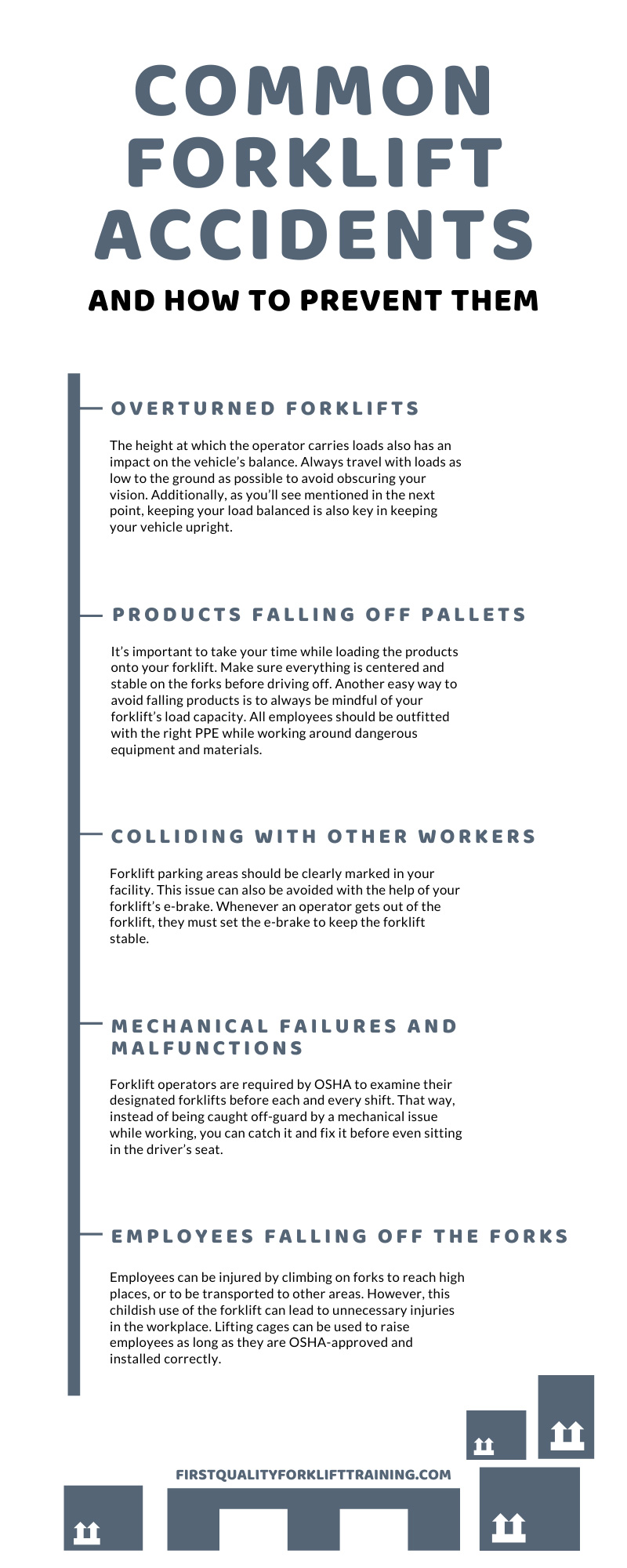

Common Forklift Accidents and How to Prevent Them

Becoming a forklift operator can be a laborious process, but there’s a reason for that. Without proper training and understanding of these common pieces of heavy machinery, you can get hurt, someone else can get hurt, or property can get damaged. Obviously, these are all things that need to be avoided in functioning, organized warehouse environments. To make sure you’re aware of the proper safety precautions in your workplace, use this guide to become familiar with the many common forklift accidents and how to avoid them.

Overturned Forklifts

Tip overs are the number 1 cause of fatalities involving forklifts. This can happen for several different reasons. For instance, pneumatic tires are designed to handle uneven terrain, which is why they are commonly used in outdoor environments. However, these tires do not negate the importance of an operator identifying the possible hazards and driving the forklift in a slow and careful manner. The speed and manner in which an operator drives plays a role in preventing overturned forklifts in the workplace. Something as simple as taking your time while turning a forklift or driving up inclines with the load in front of you can help you avoid this type of accident. Not exceeding your facility speed limits is still another example of how an operator can prevent a forklift from swerving and overturning.

The height at which the operator carries loads also has an impact on the vehicle’s balance. Always travel with loads as low to the ground as possible this keeps the center of gravity low and creates a more stable forklift. Additionally, as you’ll see mentioned in the next point, keeping your load balanced is also key in keeping your vehicle upright. As you can see, many things can lead to your forklift overturning, but these things can be easily prevented with a properly trained operator behind the wheel.

Products Falling Off Pallets

Many times damaged product is the result of traveling with unstable, unbalanced loads. This is usually the result of a poorly trained or a reckless operator. For instance, products placed off-center onto the pallet can cause products to fall off and become damaged. To avoid this from occurring, it’s important to take your time while loading the products onto your forklift. Make sure the load is centered and stable on the forks before driving off. Another easy way to avoid falling products is to always be mindful of your forklift’s load capacity. All forklifts must have capacity plates. These are commonly attached near the front of the vehicle. These not only include the forklifts load capacity at a specific height but also include other information like proper tire size.

Colliding With Other Workers

The second cause of death after tip over is when an individual is struck by a forklift. This can occur because of several factors. First, improperly trained workers can lead to a workplace collision. That’s why thorough training and certification is required for all forklift operators. Additionally, poorly marked hazard areas can lead an unsuspecting pedestrian right into the path of a forklift. It’s for that reason that clear, understandable signs and floor markings should be in place for all areas in which forklifts will be driving through.

Another way that passersby can be struck by forklifts or loads is in the case of a runaway forklift. This can happen if a forklift is abandoned in an area that isn’t an approved forklift parking spot. These forklift parking areas should be clearly marked in your facility. This issue can also be avoided with the help of your forklift’s e-brake. Whenever an operator gets out of the forklift, they must set the park brake, lower forks to ground, directional control in neutral, and turn power off. By keeping these principles in mind, you can keep your forklift from rolling away and causing damage to nearby equipment and, even worse, nearby pedestrians.

Employees Being Hit by Falling Products

If a load ever falls off the forks, it can strike nearby employees. This illustrates the importance of correctly marked forklift areas to ensure workers are safe around, and aware of, the perimeters. It’s also for this reason, and many more, that PPE is very important at all times. PPE stands for personal protective equipment and includes gear such as hard hats, goggles, and reflective vests. All employees should be outfitted with the right PPE while working around dangerous equipment and materials.

Mechanical Failures and Malfunctions

While many of the issues mentioned above can happen because of human error, they can also result from mechanical error. Someone who is new to forklifts may think that mechanical failure is out of their hands, but that’s far from the truth. It’s for this very reason that forklift operators are required by OSHA to examine their designated forklifts before each and every shift. That way, instead of being caught off-guard by a mechanical issue while working, you can catch it and fix it before even sitting in the driver’s seat. If you keep a close eye on your forklift and practice regular maintenance routines, you can refrain from experiencing a mechanical calamity while operating your truck.

Employees Falling Off the Forks

You might be wondering why employees would climb on parts of the forklift that aren’t the driver’s seat, and if you are, then you already have the right mindset for this. Employees can be injured by climbing on forks to reach high places, or to be transported to other areas. However, this unsafe use of the forklift can lead to unnecessary injuries in the workplace. If you do need to use a forklift to raise an employee, there are safe ways to do it. Lifting cages can be used to do this as long as they are OSHA-approved and installed correctly. Once you get that lifting cage installed, and with specialized training, you’ll be ready to lift employees. Note: many forklift manufactures recommend the use of a Mobile Elevating Work Platform (MEWP) rather than a fork mounted work platform.

With the right training and safety precautions, you can ensure your work environment runs efficiently and safely. As you can see, it takes following one rule to help prevent several accidents around forklifts. That’s why knowing all of the common forklift accidents and how to avoid them is one of the most important things you can keep in mind on a day-to-day basis. At First Quality Forklift Training, we’ll provide you with the ultimate forklift training package so you can teach your new employees everything there is to know about the job, including these preventable accidents.