Forklift Training & Certification

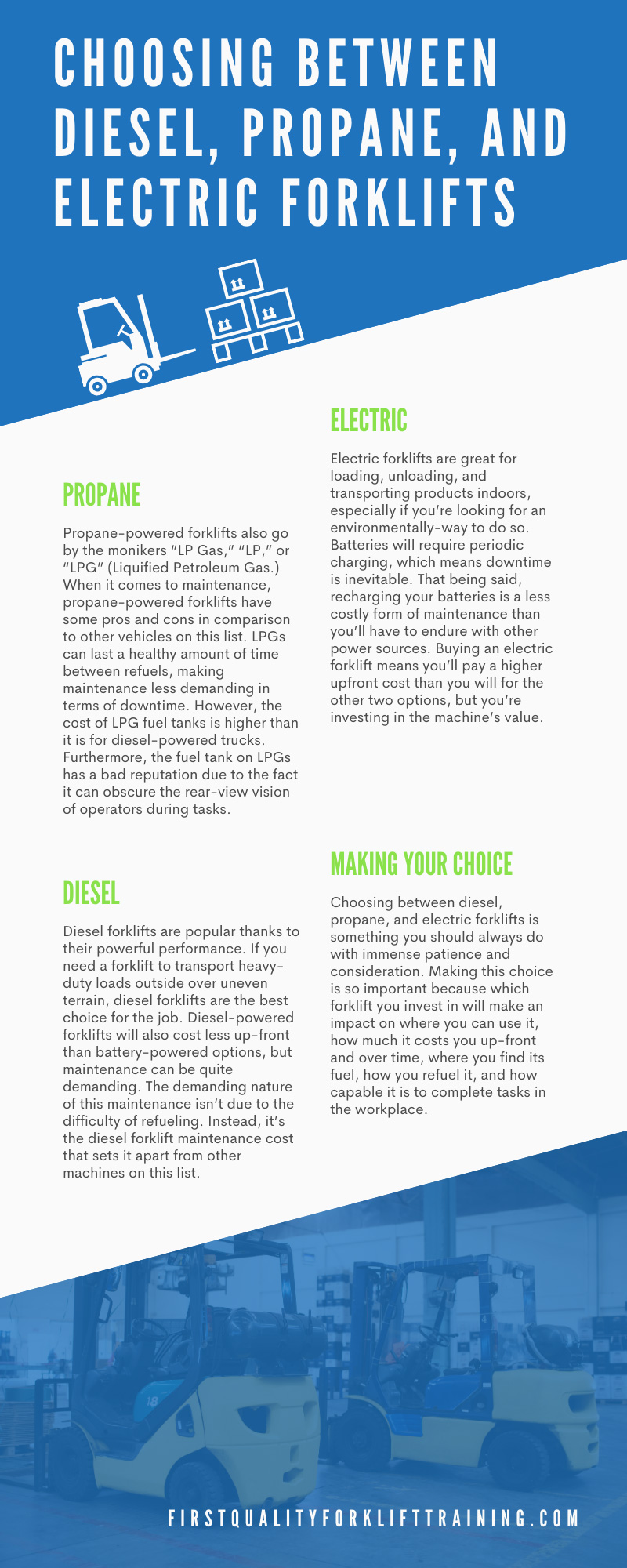

Choosing Between Diesel, Propane, and Electric Forklifts

Choosing between diesel, propane, and electric forklifts is a critical decision that all businesses must make when purchasing these industrial machines. While eco-friendly benefits set these fuel types apart, it’s far from the only difference they share. Below, we’ll take you through a comprehensive look at the pros and cons of each forklift fuel type to help you make the right choice for your company’s needs.

Diesel

Diesel forklifts are popular thanks to their powerful performance. If you need a forklift to transport heavy-duty loads outside over uneven terrain, diesel forklifts are the best choice for the job. The reason for this is that these vehicles arrive specially built to maneuver over rough terrain with ease.

That ability is a benefit of the machine’s internal combustion engine, which provides it with enough torque to successfully complete heavy-duty jobs over long distances and up and down inclines. Even in harsh cold weather, diesel trucks remain as powerful as ever.

Diesel engines also lack the environmental friendliness that other options on this list provide. For this reason, diesel engines aren’t relatively safe to use indoors. Using them indoors for a short period is okay, as long as the indoor environment has sufficient ventilation for preventing the accumulation of harmful fumes in the area. If you ever need to use diesel trucks indoors, always use the proper safety measures when doing so.

Diesel-powered forklifts will also cost less up-front than battery-powered options, but maintenance can be quite demanding. The demanding nature of this maintenance isn’t due to the difficulty of refueling. Instead, it’s the diesel forklift maintenance cost that sets it apart from other machines on this list. Another aspect that sets this truck apart from others below is the noise, which is widely considered excessive.

Propane

Propane-powered forklifts also go by the monikers “LP Gas,” “LP,” or “LPG” (Liquified Petroleum Gas.) When it comes to maintenance, propane-powered forklifts have some pros and cons in comparison to other vehicles on this list. LPGs can last a healthy amount of time between refuels, making maintenance less demanding in terms of downtime.

It also doesn’t hurt that with LPGs, you won’t experience diminishing performance during each shift. From the time you refuel an LPG to the next time you have to refuel it, the truck should provide you with a consistent level of power.

However, the cost of LPG fuel tanks is higher than it is for diesel-powered trucks. Furthermore, the fuel tank on LPGs has a bad reputation due to the fact it can obscure the rear-view vision of operators during tasks.

Luckily, propane-powered forklifts still have their own set of benefits. For instance, they are more environmentally friendly than diesel forklifts. Additionally, LPGs don’t produce the loud noise that diesel-powered trucks emit. The former is far quieter than the latter, but still not as silent as electric forklifts.

LPGs are also unique thanks to their ability to function well indoors and outdoors. Certain extreme conditions, like cold weather, can hinder an LPG’s performance, but generally they can operate outdoors successfully. Although they don’t display the same powerhouse performance as diesel trucks, propane-powered forklifts can still provide great speeds and lifting capabilities in the field.

Electric

As the name suggests, electric forklifts don’t operate via a normal fuel source like gas. Instead, upon purchase, these forklifts come with their own fuel source—a battery. Electric forklifts are great for loading, unloading, and transporting products indoors, especially if you’re looking for an environmentally-way to do so. The battery power source in an electric truck is an eco-friendly alternative to propane and diesel, though that doesn’t mean you don’t need to perform routine maintenance.

Batteries will require periodic charging, which means downtime is inevitable. That being said, recharging your batteries is a less costly form of maintenance than you’ll have to endure with other power sources. Not only is maintenance easy and cost-effective, but so is learning to operate these trucks. Electric forklifts have a knack for being easier to use than the trucks above.

Buying an electric forklift means you’ll pay a higher upfront cost than you will for the other two options, but you’re investing in the machine’s value. With that higher up-front cost, you get a machine that is simple to operate, quiet, utilizes eco-friendly technology, all while being easy and affordable to maintain.

Plus, the lifespan of electric forklift batteries in single-shift operations is about five to six years. Facilities can even extend electric forklift battery life to as long as 10 years by sticking to a routine maintenance schedule. Forklift maintenance is key not just for safety reasons, but also for keeping the battery healthy and powerful.

Remember, it’s best to use this type of forklift for indoor applications. Using most electric forklifts in outdoor environments where moisture is present can lead to mechanical malfunctions within the machine’s wiring. However, in a dry, indoor space, battery-operated forklifts can be a significant benefit to your workflow.

Something else to note about battery-operated forklifts is their lack of torque. As mentioned above, a diesel-powered forklift utilizes an internal combustion engine which provides sufficient torque for it to maneuver through rough terrain.

Since electric forklifts run on batteries, they don’t utilize an internal combustion engine and, therefore, don’t have the torque that diesel-powered options do. The lack of torque also means electric forklifts are best for ground-level operations instead of maneuvering on inclines and other uneven terrain in work environments.

Making Your Choice

Choosing between diesel, propane, and electric forklifts is something you should always do with immense patience and consideration. Making this choice is so important because which forklift you invest in will make an impact on where you can use it, how much it costs you up-front and over time, where you find its fuel, how you refuel it, and how capable it is to complete tasks in the workplace.

It’s understandable to assume “A forklift is a forklift, who cares about the power source?”, but, as you can see from the various points above, the power source of these vehicles is crucial to consider before purchasing them.

You also have to take training into account when purchasing forklifts. Be sure you can provide OSHA-compliant training courses to a new hire, specifically training courses focusing on the precise forklift models your employees will use daily in the workplace. When you’re seeking out all of the essential resources such as an OSHA forklift training video, make sure it aligns with your specific type of forklift.

Great content! Thank you for the information you have provided!