Forklift Training

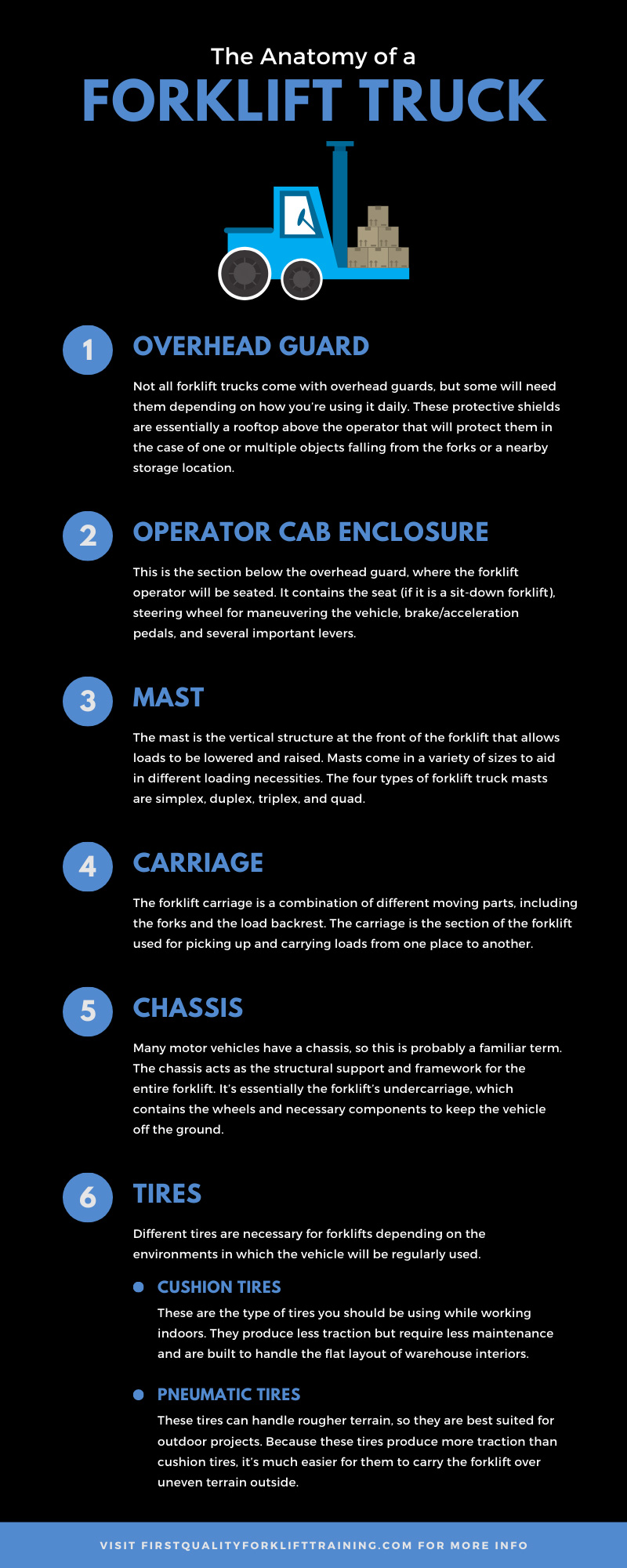

The Anatomy of a Forklift Truck

Forklifts have been a key part of transporting goods for years. If you’re going to be working with forklift trucks at your job, you’ll need to go through forklift certification training. However, there’s more to forklift training than simply knowing how to operate the machinery. You’ll need to know the anatomy of a forklift truck—all the ins and outs of the machine that cause it to function properly. Once you understand that, you’ll be one step closer to getting behind the wheel for hands-on training.

Overhead Guard

Forklift overhead guards have helped to protect operators from falling packages, boxes, and bagged materials. The overhead guard is a cage-like structure covering the overhead of the operator. They are designed with a number of small openings as to not obscure the operators view as when looking up to place and retrieve loads. OSHA has set requirements and ANSI has published standards in regards to overhead guards which include specs and testing procedures. They are required for the protection and safety of the forklift operator.

Operator Cab Enclosure

This is the section below the overhead guard, where the forklift operator will be seated. It contains the seat (if it is a sit-down forklift), steering wheel for maneuvering the vehicle, brake/acceleration pedals, and several important levers.

Operator Levers

A series of levers are located in the cab to aid in the carrying and loading processes. The lift lever is what allows the operator to control the vertical movement of the forks. Likewise the tilt lever will help with the angling of the forks when picking a load, traveling with a load and depositing a load. If equipped the third lever, is an attachment lever. Most commonly used for the carriage side shift function. The side shift lever, allows the operator to move loads horizontally. Note: there may be a fourth lever. Some uses may include control for an additional attachment or as a fork positioner.

Capacity Plate

This is located at the front of your forklift so you can easily access important information about the vehicle. Any forklift operator should become very familiar with the capacity plate on their vehicle. This plate will tell you the vehicle’s maximum lifting height, tilting degrees, carrying capacity, and even information about the tires being used.

Mast

The mast is the vertical structure at the front of the forklift that allows loads to be lowered and raised. Masts come in a variety of sizes to aid in different loading necessities. The four types of forklift truck masts are simplex, duplex, triplex, and quad.

Lift Cylinders

This hydraulic cylinder powers the movement of the mast. Specifically, the lift cylinders help power the vertical movement of the forklift mast. These cylinders are responsible for raising and lowering raising forklift carriage and the forks of loads, the actual loading process is enhanced with another type of cylinder – tilt cylinder.

Tilt Cylinders

This goes hand-in-hand with the lift cylinder, though it controls a very different kind of movement. Tilt cylinders, as the moniker suggests, control tilt movement of the load you’re carrying. Essentially, tilt cylinders help power the process of traveling, loading, and unloading products.

Carriage

The forklift carriage is a combination of different moving parts, including the forks and the load backrest extension. The carriage is the section of the forklift used for picking up and carrying loads from one place to another.

Forks

The forks, or “tines,” on the forklift are an extension of the carriage. They are the tools that operators use to physically pick up and maneuver loads. Similar to masts, forks come in a variety of shapes and sizes, allowing them to maneuver an eclectic range of loads. The type of forks used depends on the specific loads you’ll be carrying regularly.

Load Backrest Extension

This is another area of support on the carriage on which loads will rest. This section of the carriage also helps protect the mast and the operator from any objects that could come falling backward off the forks.

Chassis

Many motor vehicles have a chassis, so this is probably a familiar term. The chassis acts as the structural support and framework for the entire forklift. It’s essentially the forklift’s undercarriage, which contains the wheels and necessary components to keep the vehicle off the ground.

Steering Wheels

The steering wheel is not a reference to the literal wheel inside the cab used for steering the vehicle, strangely enough. Steering wheels are the type of wheels you’ll find at the rear end of the forklift. These wheels help operators steer and maneuver the vehicle while carrying loads.

Drive Wheels

These are the wheels you’ll find at the front end of the forklift. You’ll also notice that they are typically larger than the steering wheels. This is because drive wheels administer the necessary power needed to move the forklift from one place to another.

Tires

Different tires are necessary for forklifts depending on the environments in which the vehicle will be regularly used.

Cushion Tires

These are the type of tires you should be using while working indoors. They provide great traction on smooth surfaces and have along life. They generally offer very little ground clearance which makes them more prone to get stuck when driving on dirt or grass. To combat this problem, users may opt to put traction tires on the front of their forklifts. Traction style tires will give better traction on rough terrains like asphalt or compacted gravel. Forklifts with cushion style tires are less expensive pneumatic lift tires.

Pneumatic Tires

These tires can handle rougher terrain, so they are best suited for outdoor projects nevertheless, they can be used inside as well. Because these tires produce more traction than cushion tires, it’s much easier for them to carry the forklift over uneven terrain outside. There are three types of pneumatic tires, solid, air and air/foam. Solid pneumatic tires are made of solid rubber and are ideal when work where sharp metal, miscellaneous debris, and nails are commonplace such as scrap yards and lumber yard. Air tires tend to result in a bouncy ride and can be punctured. To reduce the bouncy effect of an all air tire, foam is added to provide a smoother ride.

Counterweight

This weight, located in the rear of a forklift truck for an IC forklift. In the case of and electric forklift the many times the counterweight is the battery and a counterweight in the rear of the forklift. The counterweight helps keep the vehicle remain stable and balanced. While carrying loads from one place to another, this counterweight will help offset the weight of the load you’re carrying. That’s why you need to be aware of your forklift’s carrying capacity. The counterweight helps keep the forklift from toppling over, but if you exceed the maximum carrying capacity, the counterweight won’t be able to properly balance the vehicle.

Power Source

Different forklifts use various types of power sources—some are operated by batteries, diesel, gas, propane, or even compressed natural gas (CNG). In fact, propane-fueled forklifts are very common because they are much easier to refuel. Unlike other power sources, propane tanks are usually located on the exterior of the forklift, making it easier to replace when the propane is depleted.

Becoming familiar with the anatomy of a forklift truck is important for anyone working with or around these large pieces of machinery. Before you begin your forklift training, you should already be very familiar with each section of the vehicle and its function. When it comes to forklift operating, it’s important to know not only how it operates depending on the levers you pull but why it operates the way it does as well.