Forklift Safety

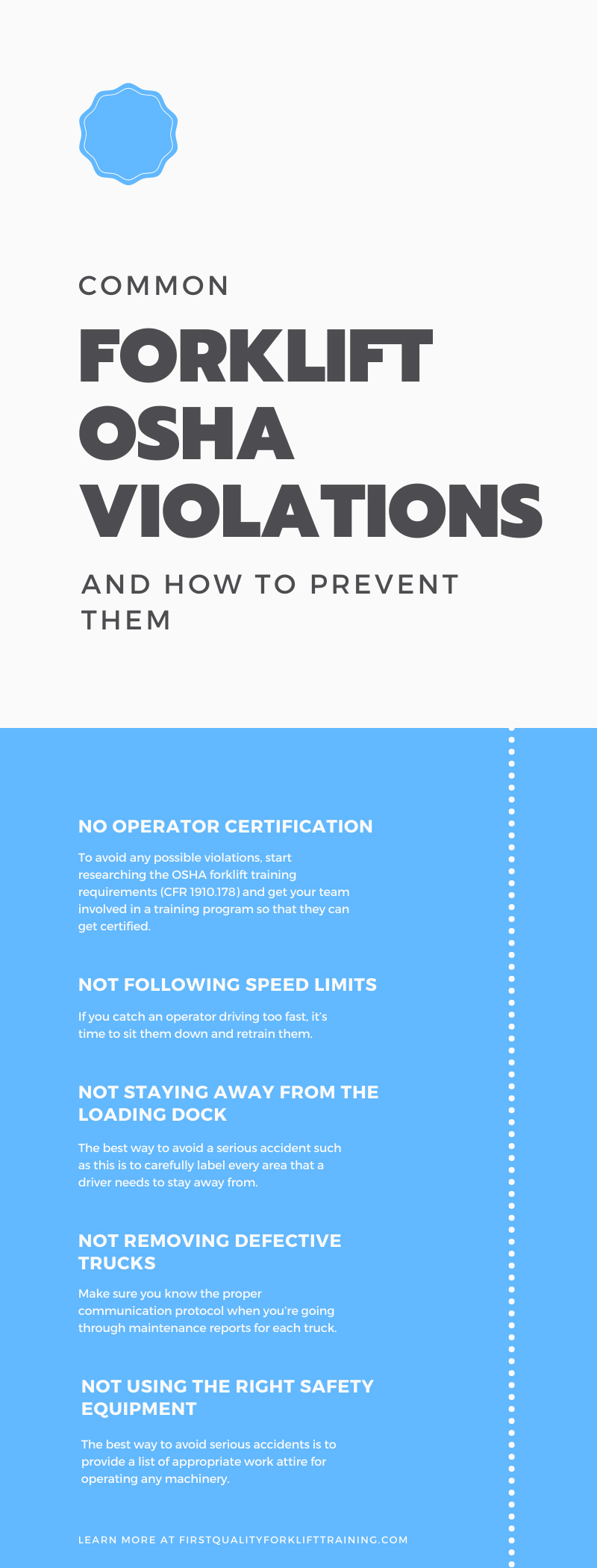

9 Common Forklift OSHA Violations and How To Prevent Them

Safety is a huge factor that one might be tempted to sacrifice to complete an integral part of a job. However, taking that risk to meet your team’s needs can get you into a ton of trouble. So familiarize yourself with these standard forklift OSHA violations and how to avoid them.

No Operator Certification

Obtaining forklift certification is crucial to ensuring each member of your crew is eligible to drive a lift. Without the correct certification, you can risk serious fines and a lawsuit if an employee gets hurt.

To avoid any possible violations, start researching the OSHA forklift training requirements (CFR 1910.178)and get your team involved in a training program so that they can get certified. Certifying all eligible workers will help supervisors remain aware of who’s allowed to drive the forklift and who’s not.

Driving With an Elevated Load

Some operators believe they can drive just fine with elevated loads. However, the higher the forks are, the more likely items are to fall and cause injury during operation. When operating a forklift, keep the load as low as possible to ensure a stable load. Furthermore, always make sure that the forks are not sloping downward.

Not Following Speed Limits

If you catch an operator driving too fast, it’s time to sit them down and retrain them. It’s important to explain to the operators that driving too fast can result in them losing control and crashing. There should never be an excuse for this, and as a supervisor, you need to enforce the rules.

Consider posting forklift safety signs and posters or speed limit signs around problem areas in the warehouse and loading dock. These visual reminders will reinforce the need for the operator to drive the forklift in a safe manner.

Not Staying Away From the Loading Dock

If a driver inches too close to the edge of a loading dock, they could end up tipping or falling off. This situation is taught in many forklift safety training videos. The best way to avoid a serious accident such as this is to carefully label every area that a driver needs to stay away from. Also, start holding safety meetings in which everyone can voice their concerns and find ways to stay safe while operating the forklift.

Not Performing Pre-Operation Inspections

The one thing many new operators forget is the daily pre-operation inspection check. OSHA requires that all forklifts be inspected at the beginning of each shift. Forgetting these is a big problem that can result in accidents and cause the lift to break down. The only way to avoid this is to require everyone to always do an inspection before they operate a forklift. These inspections involve inspecting the basics, such as the fluid levels, the battery, and even the headlights of the lift.

If someone forgets a step, have them go through the process again, and consider retraining them. Also, post signs near the parking area to remind drivers to check their forklifts before each use.

Not Providing Refresher Training

Every employer needs to understand the importance of refresher training. OSHA requires refresher training:

- When an operator has been involved in an accident or near miss;

- When an operator has been observed operating unsafely; and

- If the types of forklifts being operated change or the workplace changes to affect safe operation.

A refresher training session requires unsafe operators to relearn skills and update their current knowledge. Have every worker periodically retake a forklift operating class to renew their skills and become safer drivers. With this refresher training, workers will gain more in-depth knowledge on performing pre-operational checks, such as observing any mechanical problems and removing obstructions from their forklift’s path.

Not Removing Defective Trucks

Forklift operators need to fill out reports during each pre-operational inspection. However, if an employer doesn’t follow up and remove any defective trucks, the truck will make the overall environment very unsafe until the problem is resolved.

To avoid that, make sure you know the proper communication protocol when you’re going through maintenance reports for each truck. If there’s a maintenance issue—for example, if the brakes don’t work or if the machine is completely inoperable—you need to tag the forklift and remove the key. The forklift should not be used until it is repaired, and it must then go through a complete pre-operation inspection before use.

Not Using the Right Safety Equipment

Having the right safety gear is crucial for forklift operation. Without it, your employees risk harming themselves and others around them. It’s essential that all crewmembers who are certified to drive have the right equipment.

The best way to avoid serious accidents is to provide a list of appropriate work attire for operating any machinery. Equipment such as protective eyewear and safety shoes can protect workers. Additionally, if you have electric forklifts, make sure to provide an eyewash station in case a worker gets something in their eyes. The eyewash station will provide quicker relief from chemical exposure; after the employee washes out their eyes for at least 10 minutes, have them seek medical attention.

Not Providing Adequate Fall Protection

OSHA requires that all Class II narrow aisle and order picker forklift operators always wear the proper personal protective equipment (PPE). This includes a body harness and lanyard. It’s also important to provide proper training in the use of the harness and lanyard.

These common forklift OSHA violations and how to avoid them are here to remind you of what you need to be aware of in the future. Keep all your forklift operators and supervisors updated on violations, and teach them how to avoid causing accidents and creating issues. Work with them to improve the safety standards of your warehouse. After they complete their training, they’ll be aware of what to do when working around forklifts.

First Quality Forklift Training provides training on preventing workers from causing violations. Workers—yourself included—can learn how to prevent issues from happening with a forklift training program that goes over all violations. Contact us here for more information on our forklift training programs, which go over all the OSHA safety requirements.

Thanks for sharing this information about forklifts OSHA violations. This information is very helpful.

What if another employee continues to shut off access to the propane tank on a forklift they have not been using or inspected as some sort of “joke” on other individual that has stepped away from the forklift they are using? Mind you, it was always parked safely with keys out.

Definitely a safety issue and I’d assume an OSHA violation. Should you step away from your forklift and assume another inspection no matter what or is what I’m talking about considered tampering?

Is sitting on box while driving a stand up fork lift a violation. It defeats the emergency break in my opinion by not taking the weight off the pedals, am I wrong?

NOT A COMMENT BUT A QUESTION. WHAT THE RULES AND REGULATION ON SOMEONE DRIVING THE FORKLIFT WITH THE BLADES UP AND CAUSE AN ACCIDENT OR LOADING AND UNLOADING AND CAUSE AN ACCIDENT OR THE BLADES ARE UP TO THE STREET AND CAUSE AN ACCIDENT