Pedestrian Safety

8 Benefits of Forklift LED Warning Lights

Below Are 8 Benefits of Forklift LED Warning Lights

1. Creates a Visible Border

2. Compliments Current Regulations

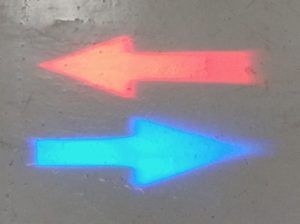

OSHA regulates that all forklifts must be provided a sound producing device – most common ‘horn’ (Equip every power-propelled truck with an operator-controlled horn, whistle, gong, or other sound-producing device. ANSI B56.1-1969 Incorporated by reference [29 CFR 1910.178(a)(2)]). At critical locations like cross aisles and other areas where the vision is obstructed, drivers are advised to slow down and sound horns to warn the pedestrians of incoming forklifts. Drivers are asked to use a combination of sounds and warning lights. Back up alarms are very irritating to workers. These safety devices are sometimes intentionally disabled by forklift operators as they can be very annoying. The sound of backup alarms may fade into the ambient noise. Forklift LED warning lights have the advantage of being very unobtrusive. These spotlights which come in red and blue colors can accurately indicate which direction the forklift is coming from and how fast it is moving.3. Capture Pedestrian Attention Easily

4. Easy To Install

The installation is very simple and doesn’t require much time. The LED pedestrian safety warning spotlights come with an aluminum housing which is very durable. Easy mount bracket can be used to mount the LED spotlights securely on the lift trucks without drilling into overhead guard (drilling into overhead guard reduces capacity and should not be done without first contacting forklift manufacturer). To ensure maximum safety, it is recommended to install a red spotlight in the front and a blue LED light in the back (or vise-versa). The lights must be wired in such a way that when the forklift is moving in one direction, only the relevant light must turn on so that people can easily identify which direction it is moving. While implementing, it is very important to keep consistency across all vehicles, especially in the distance of beam from the truck and the color of light used in the front and back. Changes in these parameters can lead to dangerous assumptions on the part of pedestrians and other forklift operators. LED warning lights are ideal for installation on different classes of forklifts like Class I (stand up rider and sit-down lift trucks), Class II Narrow Aisle (order pickers and reach trucks), Class III (electric pallet jacks), Class IV (cushion tire sit-down forklifts), Class V (pneumatic sit-down forklifts), Class VI (tuggers or tow tractors i.e. used in airports), Class VII (rough terrain forklifts) and even pedestrian transport vehicle i.e. golf carts. LED spotlights are safe for installing on any piece of industrial equipment.5. Highly Durable

Solid state LED lights are very sturdy and are capable of withstanding shock and vibration. This is very important with forklifts as they lack traditional suspension systems. LED lights do not have any fragile components like glass envelopes that is present in fluorescent, incandescent,and metal-halide lighting sources. In addition, they also do not have any filaments that might break leading to failure. So, there is no risk of sustaining damage during transportation. These safety warning spotlights are long-lasting. LED lights have a lifespan of 50000+ hours. So, there is no need to worry about catastrophic failure at critical points. Maintenance and repair overhead can be greatly reduced by installing LED forklift pedestrian safety warning spotlights.6. Auto-darkening Welding Helmet Friendly

It’s awesome that forklift LED lights don’t need any time to warm up like other LED lights do. That would really save time for the operator of the lift. I bet it would be important to know how to operate the forklift using the lights on the sides, so a safety course would probably be a necessary thing for anyone driving the machine. My son was talking about how he wanted to get certified to operate a forklift, so I’ll tell him to learn about these lights as well in whatever course he takes so he’ll know how to use them.

Great post on forklift. Look forward to seeing more blogs from you..

nice blog . its amazing!

Thanks for sharing such great information about Forklift LED Warning Lights. Forklift LED warning lights can be used to force the pedestrians to keep a safe distance during work activities.

You made an interesting point when you explained that modern technology can take forklift safety lights to the next level. I would imagine that it would be important to inspect forklifts before using them so that accidents don’t occur. It seems like it would be a good idea to get some kind of diagnostic tool that can help with these inspections.

This article highlights the key benefits of forklift LED warning lights exceptionally well! It’s a great resource for understanding how these lights enhance workplace safety and efficiency.